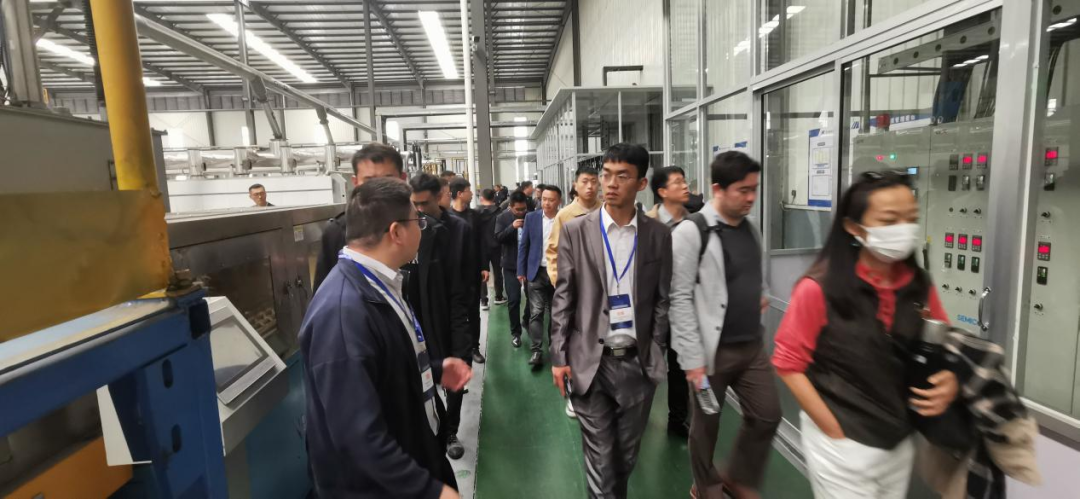

Like it! Workshop opens new production line! More than 120 lithium battery peers nationwide have formed a group to check in this enterprise! Take out your phone and shoot wildly!

Release time:

2023-08-31

On April 14th, Qingdao Xintaihe Nanotechnology Co., Ltd., located in Yuanshang Town, Laixi City, Qingdao City, Shandong Province, welcomed a special group of guests -120 well-known entrepreneurs and university professors in the lithium battery negative electrode industry who participated in the "2023 Lithium Battery Negative Electrode Materials and Raw Materials Market Summit Forum and the 5th International Natural Graphite and Application Market Summit Forum" organized by Xinluo Information.

On April 14th, Qingdao Xintaihe Nanotechnology Co., Ltd., located in Yuanshang Town, Laixi City, Qingdao City, Shandong Province, welcomed a special group of guests -120 well-known entrepreneurs and university professors in the lithium battery negative electrode industry who participated in the "2023 Lithium Battery Negative Electrode Materials and Raw Materials Market Summit Forum and the 5th International Natural Graphite and Application Market Summit Forum" organized by Xinluo Information. This group of guests specially came to visit the production workshop of Xintaihe to understand the production process and technology of the enterprise, and to explore industry development trends.

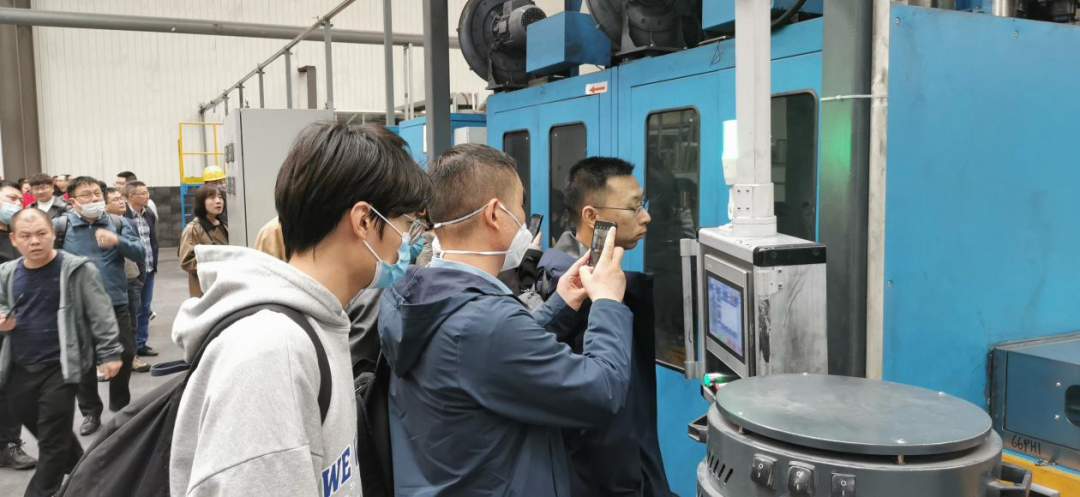

Under the guidance of on-site staff and interpreters, the visitors first entered the mixing workshop of Xintaihe. In the mixing workshop, entrepreneurs see the process of raw materials being mixed. Xintaihe adopts efficient high-temperature drying and screening demagnetization equipment to ensure uniformity and fineness of mixing. Everyone praised the advanced mixing process adopted by Xintaihe and eagerly inquired about the key parameters and technologies during the mixing process.

Next, the visitors went to the carbonization workshop. The carbonization workshop is one of the important links in the production process of lithium negative electrode materials. Xintaihe adopts a high-temperature carbonization process to ensure the safety of the production process. Entrepreneurs carefully observed the main equipment such as carbonization furnaces and oil pumps in the workshop, and learned about the carbonization process flow of Xintaihe.

Finally, the entrepreneur visited the company's finished product packaging workshop. In the finished product packaging workshop, Xintaihe has adopted automated packaging equipment to improve packaging efficiency and product quality. The entrepreneur affirmed Xintaihe's finished product packaging technology and discussed with technical personnel the future development direction of packaging technology.

Throughout the entire visit, the entrepreneurs gave high praise to their mentality, production workshop environment, and equipment status, while also expressing confidence in the development prospects of the lithium battery negative electrode material industry. Many visitors believe that lithium-ion negative electrode materials, as an important component of the new energy industry chain, will play an increasingly important role in future energy transformation. At the same time, new technologies and processes need to be constantly introduced to improve product quality and industrial competitiveness.

This visit is not only an important opportunity for Xintai and Nano Technology Co., Ltd. to showcase its production strength and technological advantages, but also a platform for the business and academic communities in the field of lithium battery negative electrode materials to exchange and learn from each other. I believe that with the joint efforts of the industry, the lithium battery negative electrode material industry will achieve more outstanding achievements, making greater contributions to energy transformation and environmental protection.

Scholars who visited the site also stated in an interview with Xinlun Information that lithium battery companies should continuously innovate, actively research and develop new technologies and materials to cope with market changes and demands, and maintain competitiveness and leading position.

The person in charge of on-site reception at Xintai and Nano also stated that they will continue to be committed to the research and production of lithium battery negative electrode materials, continuously improving product quality and technical level to meet market and customer needs. At the same time, we will actively practice the concept of green development, promote environmental protection and sustainable development.

It can be foreseen that with the continuous development and popularization of the new energy industry, the prospects of the lithium battery negative electrode material industry will become increasingly broad. The attention and support of entrepreneurs will also inject more impetus and vitality into the development of the industry.

Related News